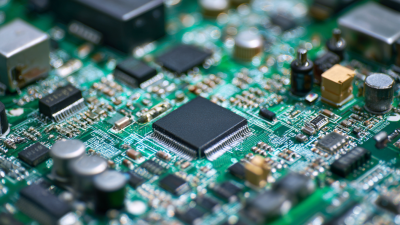

WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

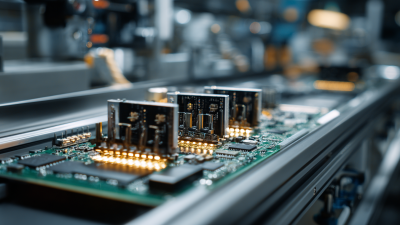

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

Learn MoreIn today's rapidly evolving technological landscape, the demand for efficient and reliable electronic assembly has surged, driving businesses and DIY enthusiasts alike to explore various approaches to production. A recent industry report from Market Research Future indicates that the global electronics manufacturing market is projected to reach over $1 trillion by 2025, emphasizing the critical role electronic assembly plays within this sector. This growth presents a compelling question: should individuals and small businesses opt for DIY electronic assembly, or engage professional services?

While DIY assembly caters to innovators seeking cost-effective solutions and hands-on experience, professional services offer expertise and scalability essential for complex projects. As we delve deeper into the nuances of these two approaches, we will uncover the key differentiators that can significantly impact quality, efficiency, and overall project success in electronic assembly.

The rise of DIY electronics is closely intertwined with market trends that reflect a growing appetite for individual creativity and hands-on projects. As the global outdoor power equipment (OPE) market is projected to grow from $37.36 billion in 2025 to $54.24 billion by 2032, with a compound annual growth rate (CAGR) of 5.47%, this trend signals a robust interest in personal and customizable solutions. Additionally, in the consumer electronics sector, China's assembled computer market has bucked global downturns, expecting an impressive growth from 44.707 billion yuan in 2016 to 65.56 billion yuan in 2023. This growth showcases how DIY enthusiasts are reshaping the landscape by transforming standard components into personalized devices, fostering an environment where creativity meets technology.

Furthermore, the DIY movement is not limited to computers; it permeates various sectors, reflecting a significant consumer shift toward self-assembled products, including electric bikes and home cleaning solutions. As sustainability becomes a major concern, more consumers are seeking ways to maintain and repair their electronics, leading to a burgeoning market projected to reach $254.3 billion by 2032. This trend not only highlights the desire for personalized ownership but also signifies a collective movement towards environmental consciousness, encouraging makers and DIYers to embrace self-sufficiency in their electronic projects.

When deciding between DIY electronic assembly and professional services, several key factors come into play. One significant consideration is the complexity of the project. For straightforward tasks or small-scale projects, DIY assembly can be a cost-effective and rewarding option. Enthusiasts often enjoy the hands-on experience, allowing them to customize elements according to their preferences. However, for intricate designs or larger systems, professional services may provide the expertise and efficiency required to ensure reliability and performance.

Another crucial factor is the time commitment involved. DIY assembly often demands substantial time investment for research, preparation, and assembly, which may not be feasible for everyone. On the other hand, professional services can save time, quickly delivering a polished final product. Budget is also a key consideration; while DIY can potentially reduce costs, unforeseen challenges might lead to higher expenses. By evaluating these factors—complexity, time, and budget—individuals can make informed decisions that align with their specific needs and capabilities.

When it comes to assembling electronic components, the quality control between DIY electronic assembly and professional services varies significantly. DIY enthusiasts often rely on personal knowledge and available online resources, which can lead to inconsistent outcomes. Without strict quality control measures, the risk of faulty connections or component failures increases, potentially affecting the overall functionality and safety of the device. While the learning experience can be rewarding, the lack of rigorous testing methods often leaves DIY projects vulnerable to issues that could have been easily avoided.

In contrast, professional assembly services typically employ standardized processes and advanced quality assurance techniques. Experienced technicians follow strict guidelines to ensure that each component is correctly assembled and tested before leaving the facility. This professional oversight not only mitigates risks but also enhances reliability. Furthermore, these services often utilize specialized equipment to conduct thorough inspections throughout the assembly process, ensuring that the final product meets industry standards. In this context, while DIY projects may offer flexibility and personal satisfaction, the superior quality control provided by professionals makes it a more reliable choice for critical electronic applications.

Cost analysis of DIY electronic assembly versus professional services reveals several factors that can influence your decision. While DIY may initially seem more economical, it is essential to consider both direct and indirect costs associated with the assembly. Tools, materials, and potential errors can quickly add up. On the other hand, professional services often come with a higher upfront cost but can save you time and ensure quality.

**Tip 1:** Before diving into a DIY project, create a detailed budget that includes all necessary materials and tools. This will help you accurately assess whether you are saving money compared to hiring professionals.

Additionally, experience plays a crucial role in the overall cost-effectiveness of DIY assembly. Beginners may encounter a steep learning curve, sometimes resulting in wasted components and a longer project timeline. Conversely, professionals bring expertise that minimizes mistakes and enhances efficiency.

**Tip 2:** If you're leaning toward DIY, consider collaborating with someone who has experience in electronic assembly. This partnership can provide valuable insights and reduce the likelihood of costly errors.

| Assembly Method | Estimated Cost per Unit ($) | Time Required (Hours) | Skill Level Required | Quality Consistency (1-10) |

|---|---|---|---|---|

| DIY Assembly | 10 | 5 | Intermediate | 7 |

| Professional Assembly | 25 | 2 | Expert | 9 |

| Bulk Orders (DIY) | 8 | 4 | Intermediate | 8 |

| Bulk Orders (Professional) | 20 | 1 | Expert | 10 |

When considering DIY electronic assembly, the learning curve plays a crucial role in determining success. Unlike professional services, which typically employ skilled technicians, DIY enthusiasts must acquire a range of competencies to effectively build and troubleshoot their projects. Fundamental skills include basic electronics knowledge, such as understanding voltage, current, and resistance, as well as familiarity with various components like resistors, capacitors, and microcontrollers. This foundational knowledge not only aids in assembling circuits but also fosters confidence in innovative projects.

Moreover, hands-on skills are paramount in the DIY realm. Soldering, for instance, is a critical technique that requires practice to master. Effective soldering ensures reliable connections and longevity of the assembled device. Additionally, troubleshooting skills are necessary for diagnosing issues that arise during assembly or operation. By learning how to read circuit diagrams and use diagnostic tools like multimeters, DIY enthusiasts can enhance their problem-solving skills, ultimately leading to a more adept and enjoyable building experience. Embracing this learning curve not only makes DIY electronic assembly feasible but also rewarding, as individuals see their knowledge translate into tangible creations.