WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

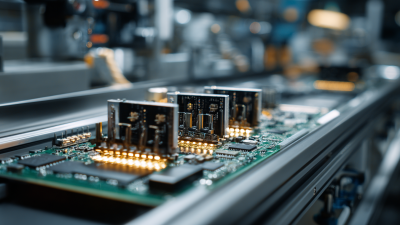

Learn MoreIn the highly competitive landscape of the manufacturing industry, optimizing production processes is paramount, and one key area that often requires improvement is the board assembly process. According to a report from MarketsandMarkets, the global printed circuit board (PCB) market is expected to reach $80 billion by 2026, driven by advancements in technology and increasing consumer demand. Effective board assembly not only reduces time-to-market but also enhances product quality, thereby directly impacting an organization’s bottom line.

A strategic approach to board assembly processes can lead to significant operational efficiencies, reduce costs by up to $30%, and improve overall product reliability. As manufacturing continues to evolve with the integration of automation and smart technologies, developing effective board assembly strategies becomes essential for manufacturers aiming to stay ahead of the competition and meet the burgeoning demands of their clients.

Effective board assembly processes in manufacturing are crucial for driving innovation and ensuring sustainability within the industry. A solid board assembly process not only enhances regulatory compliance but also fosters robust business practices that contribute to long-term success. Reports indicate that companies with effective governance frameworks are more successful in attracting and retaining top talent, enhancing customer loyalty, and building a positive reputation in the marketplace. According to recent data, organizations demonstrating good governance practices can see a 20% increase in employee satisfaction, which directly impacts overall productivity.

Key components of an effective board assembly process include clear communication channels, stakeholder engagement, and a focus on performance metrics. A survey of manufacturing companies reveals that 65% of boards prioritize enhancing communication strategies with stakeholders to improve decision-making and accountability. Furthermore, strengthening core competencies through targeted governance strategies, such as aligning board objectives with innovation goals, lays a foundation for companies to navigate the complexities of modern manufacturing. As industries evolve, leveraging these components within board assembly processes will enable firms to adapt to and thrive in a rapidly changing economic landscape.

In the fast-paced world of manufacturing, optimizing board assembly workflows is essential for enhancing productivity and ensuring high-quality outputs. One innovative technique gaining traction is the integration of automation tools that streamline repetitive tasks. By utilizing robotic arms for component placement, manufacturers can significantly reduce assembly time and minimize human error. Coupled with machine learning algorithms, these tools can adapt to variations in production runs, making them invaluable for maintaining efficiency in dynamic manufacturing environments.

Another effective strategy is the implementation of modular assembly systems. This approach allows teams to work on different segments of the board simultaneously, promoting parallel processing. By restructuring workflows into smaller, manageable units, manufacturers can enhance collaboration and expedite the overall assembly process. Furthermore, the use of digital dashboards provides real-time tracking of progress, enabling quick adjustments and smoother transitions between stages. Together, these innovative techniques create a more agile and responsive board assembly process, positioning manufacturers to meet market demands more effectively.

Effective communication within board assembly teams is crucial for enhancing productivity and minimizing errors in the manufacturing process. One of the best practices to foster this communication is the implementation of regular stand-up meetings. These brief, focused gatherings allow team members to discuss progress, address challenges, and align their objectives. By ensuring everyone is on the same page, teams can respond quickly to any issues that arise and maintain a steady workflow.

Another key strategy is to utilize collaborative digital tools for real-time communication. Platforms that facilitate document sharing and instant messaging can keep team members informed and engaged, regardless of their physical location. Encouraging open communication channels not only enhances transparency but also nurtures a culture of feedback. When team members feel comfortable sharing their thoughts and ideas, it leads to improved problem-solving and innovation in board assembly processes. Embracing these practices can significantly boost team dynamics and drive successful outcomes in manufacturing environments.

In the competitive landscape of manufacturing, leveraging technology in the board assembly process is essential for enhancing efficiency and productivity. According to a report by the International Electrotechnical Commission, implementing automated systems can reduce assembly time by up to 30%. Technologies such as robotics and advanced automation tools are transforming traditional assembly lines into smart manufacturing environments, where tasks that once required manual labor are now executed with precision and speed. This shift not only minimizes human error but also allows for greater scalability in production processes.

Moreover, the integration of Internet of Things (IoT) technology provides real-time data analytics that help manufacturers make informed decisions. A study by Deloitte highlights that companies utilizing IoT solutions can see a 20% improvement in operational efficiency. By monitoring equipment performance and assembly workflow through connected devices, manufacturers can identify bottlenecks and optimize production schedules, ultimately leading to a more streamlined assembly process. Embracing these technological advancements is crucial for manufacturers looking to maintain a competitive edge and meet the ever-increasing demands of the market.

| Strategy | Description | Technology Used | Efficiency Improvement (%) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Automated Assembly Lines | Utilizing robots to perform repetitive tasks in board assembly. | Robotics, AI | 30% | 12 |

| Digital Twin Technology | Creating a virtual model of the production process for simulations. | Simulation Software | 25% | 8 |

| Cloud-based Collaboration Tools | Facilitating real-time collaboration among team members. | Cloud Platforms | 15% | 4 |

| Inventory Management Systems | Automating inventory tracking and management. | ERP Software | 20% | 6 |

| Data Analytics | Analyzing production data to identify inefficiencies. | Big Data Tools | 35% | 10 |

Effective training and development strategies are essential for optimizing board assembly processes within the manufacturing sector. According to a report by the Manufacturing Institute, companies that invest in employee training see a 24% increase in production efficiency. This statistic highlights the significant impact that targeted training can have on assembly line performance. Implementing structured training programs not only enhances employee skills but also reduces error rates, leading to a more streamlined assembly process.

Moreover, fostering a culture of continuous learning is vital. The Deloitte Insights 2023 report reveals that organizations focusing on employee development experience 14% higher employee engagement levels. Engaged employees are more likely to contribute innovative ideas and improvements to assembly practices, driving overall business success. By prioritizing ongoing training initiatives and promoting a collaborative learning environment, manufacturing firms can ensure their board assembly teams remain agile and responsive to industry demands.