WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

Learn MoreIn today's fast-paced technological landscape, the significance of effective electronics assembly processes cannot be overstated. As the demand for electronic devices continues to rise, manufacturers are under increasing pressure to deliver high-quality products efficiently and reliably. The intricacies of electronics assembly involve multiple stages, from component selection to final inspection, each requiring meticulous attention to detail. To thrive in this competitive environment, organizations must adopt best practices that streamline their operations, reduce waste, and enhance overall performance.

This article presents ten essential tips for achieving success in electronics assembly, offering valuable insights into optimizing workflows and improving product quality. By implementing these strategies, companies can minimize errors, accelerate production timelines, and ultimately satisfy customer expectations. Understanding the nuances of electronics assembly not only empowers manufacturers to produce reliable products but also positions them to adapt to evolving market demands. In the following sections, we will delve into the key approaches that can transform your electronics assembly processes into a well-oiled machine, ensuring sustainable growth and innovation in this dynamic field.

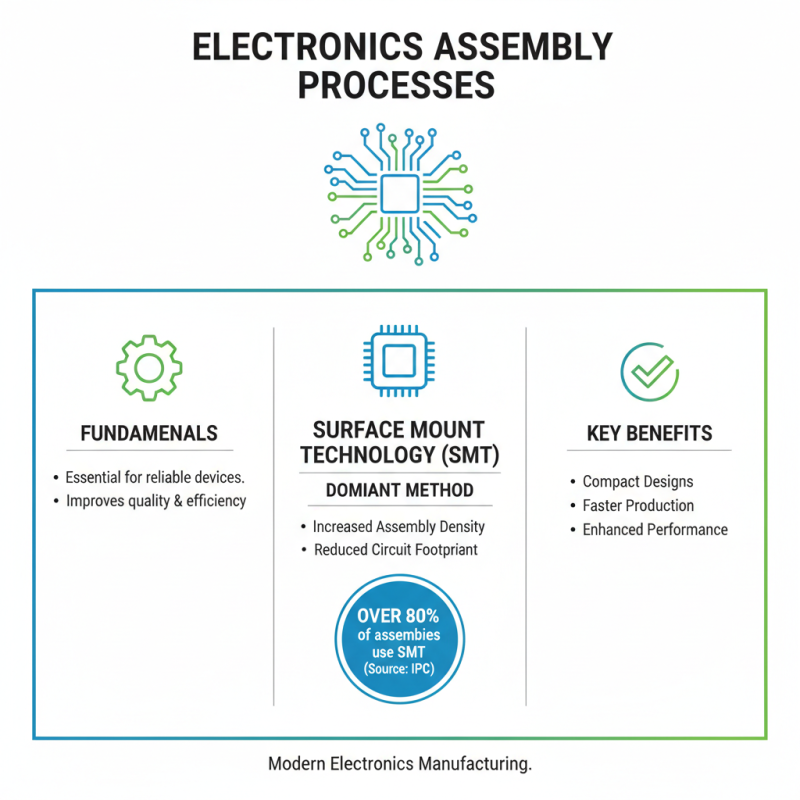

Electronics assembly processes are foundational to the production of reliable electronic devices. Understanding the basics of these techniques can significantly enhance the quality and efficiency of manufacturing. For instance, surface mount technology (SMT) has become a dominant method in the industry due to its ability to increase assembly density and reduce the overall footprint of electronic circuits. According to a report by IPC, an industry trade association, over 80% of electronic assemblies utilize SMT, highlighting its crucial role in modern electronics manufacturing.

In addition to SMT, another essential technique is through-hole technology, which remains relevant for specific applications requiring robust mechanical connections. Studies indicate that while SMT is preferred for high-tech consumer electronics, through-hole methods are still widely used in military and aerospace applications where durability is paramount. Furthermore, the integration of automated assembly systems is reshaping the landscape; a recent market analysis projected that automation in electronics assembly could enhance productivity by up to 30%, allowing manufacturers to meet growing demands efficiently while maintaining high quality standards. Understanding these assembly techniques not only aids in process selection but also empowers engineers to innovate within their designs, ensuring products are both functional and reliable.

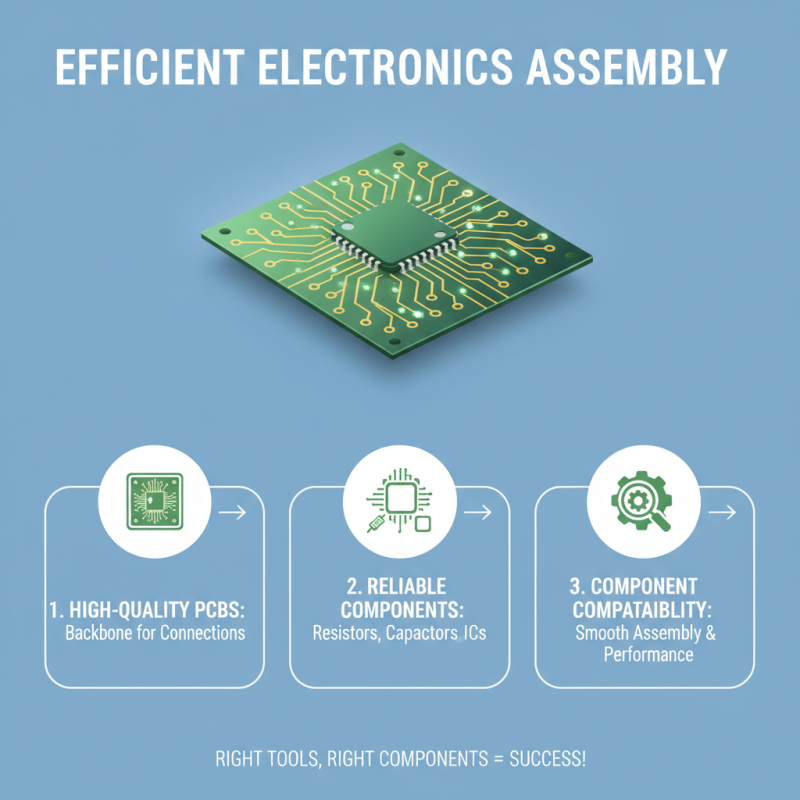

When it comes to efficient electronics assembly, having the right components and tools is crucial. First and foremost, the assembly process relies heavily on high-quality printed circuit boards (PCBs). These boards serve as the backbone for most electronic devices, providing the necessary connections for various components. Alongside PCBs, a reliable selection of electronic components, such as resistors, capacitors, and integrated circuits, ensures that the design functions correctly and meets performance standards. Understanding the specifications and compatibility of these components is essential for a smooth assembly process.

In addition to components, the tools used during assembly play a significant role in promoting efficiency. Soldering stations, for instance, are indispensable for secure connections between components and PCBs. A good soldering iron with adjustable temperature settings can enhance precision and prevent damage to sensitive parts. Moreover, using tools like tweezers and fine-tip pliers can facilitate the handling of small components in tightly packed spaces. Finally, investing in automated assembly machines can significantly reduce labor costs and improve speed, making them an excellent addition for larger production runs. Combining quality components with the right tools sets the foundation for a successful electronics assembly process.

In the realm of electronics assembly, maintaining stringent quality control is paramount to ensuring the reliability and performance of the final product. Quality control involves systematic testing and inspection processes that help identify defects and areas for improvement. By integrating quality assurance measures at every stage of the assembly process, manufacturers can significantly reduce errors and enhance overall efficiency.

One essential tip for successful electronics assembly is to implement a robust testing protocol during production. Regular audits and checks help catch potential issues early on, preventing costly reworks later. Another important strategy is to invest in employee training. Well-trained staff who are familiar with the nuances of quality standards can recognize and address problems effectively. Additionally, utilizing advanced technology, such as automated inspection tools, can streamline the quality control process and provide real-time feedback on assembly quality.

Moreover, cultivating a culture focused on quality within the organization encourages employees to take ownership of their work. Setting clear quality metrics and encouraging open communication regarding potential defects can lead to continuous improvement. By prioritizing quality control in electronics assembly processes, manufacturers not only ensure product reliability but also increase customer satisfaction, fostering long-term success in a competitive market.

In the realm of electronics assembly, professionals often encounter various challenges that can hinder efficiency and quality. One common difficulty is ensuring consistent soldering quality, which is critical for reliable connections. To mitigate this, it's essential to invest in training and using automated soldering equipment, as well as regularly inspecting solder joints. This helps in reducing defects and ensuring that the final product meets rigorous standards.

Another prevalent issue is managing component placement accurately. Misalignment during assembly can lead to functional failures. Implementing a robust verification process, such as using vision systems for automated optical inspection, can significantly enhance accuracy. Additionally, it’s important to standardize the assembly processes which can further help in preventing errors and streamlining production.

Tips such as maintaining a clean assembly environment, employing a thorough parts inspection before assembly, and fostering strong team communication can also contribute to overcoming these challenges. Emphasizing continuous improvement and regularly revising assembly protocols will keep the processes efficient and help adapt to the evolving landscape of electronics manufacturing.

| Tip Number | Tip Description | Common Challenges | Solutions |

|---|---|---|---|

| 1 | Ensure Proper Component Orientation | Incorrect placement of components | Use clear labels and orientations |

| 2 | Maintain Clean Work Environment | Contamination of components | Implement strict cleaning protocols |

| 3 | Use Quality Solder Materials | Poor electrical connections | Choose reliable solder suppliers |

| 4 | Implement Proper Training | Inexperienced workers | Regular training sessions and evaluations |

| 5 | Utilize Automation Where Possible | Inefficiencies in manual processes | Invest in automated assembly technologies |

| 6 | Conduct Regular Quality Checks | Defective products | Establish quality control checkpoints |

| 7 | Ensure Proper Component Storage | Component damage | Use climate-controlled storage |

| 8 | Optimize Layout Design | Inefficient workflow | Plan the layout for minimal movement |

| 9 | Utilize Feedback Loops | Failure to adapt | Gather feedback and implement improvements |

| 10 | Stay Updated with Technology Trends | Obsolescence of methods | Attend workshops and industry conferences |

Managing workflow in electronics assembly production is crucial for maintaining efficiency and ensuring a high-quality output. To achieve a seamless process, it's essential to implement best practices that streamline operations and minimize errors. One key strategy is to establish clear communication channels among all team members. This ensures that everyone is aligned on their tasks and responsibilities, reducing the likelihood of misunderstandings that can lead to delays.

Another important tip is to maintain an organized workspace. A tidy environment allows workers to find tools and components quickly, preventing downtime that can occur when searching for materials. Implementing visual management tools, such as labels and color coding, can also enhance the organization and speed of the workflow.

Regular training and skill development for employees play a vital role in optimizing production processes. Encouraging team members to stay updated on the latest technologies and techniques ensures that the assembly line operates at peak performance. By focusing on these essential tips—communication, organization, and continuous training—companies can significantly enhance their electronics assembly processes.

This bar chart illustrates the effectiveness of various best practices in managing workflow during the electronics assembly process. The data shows the improvement percentage in efficiency after implementing each tip.