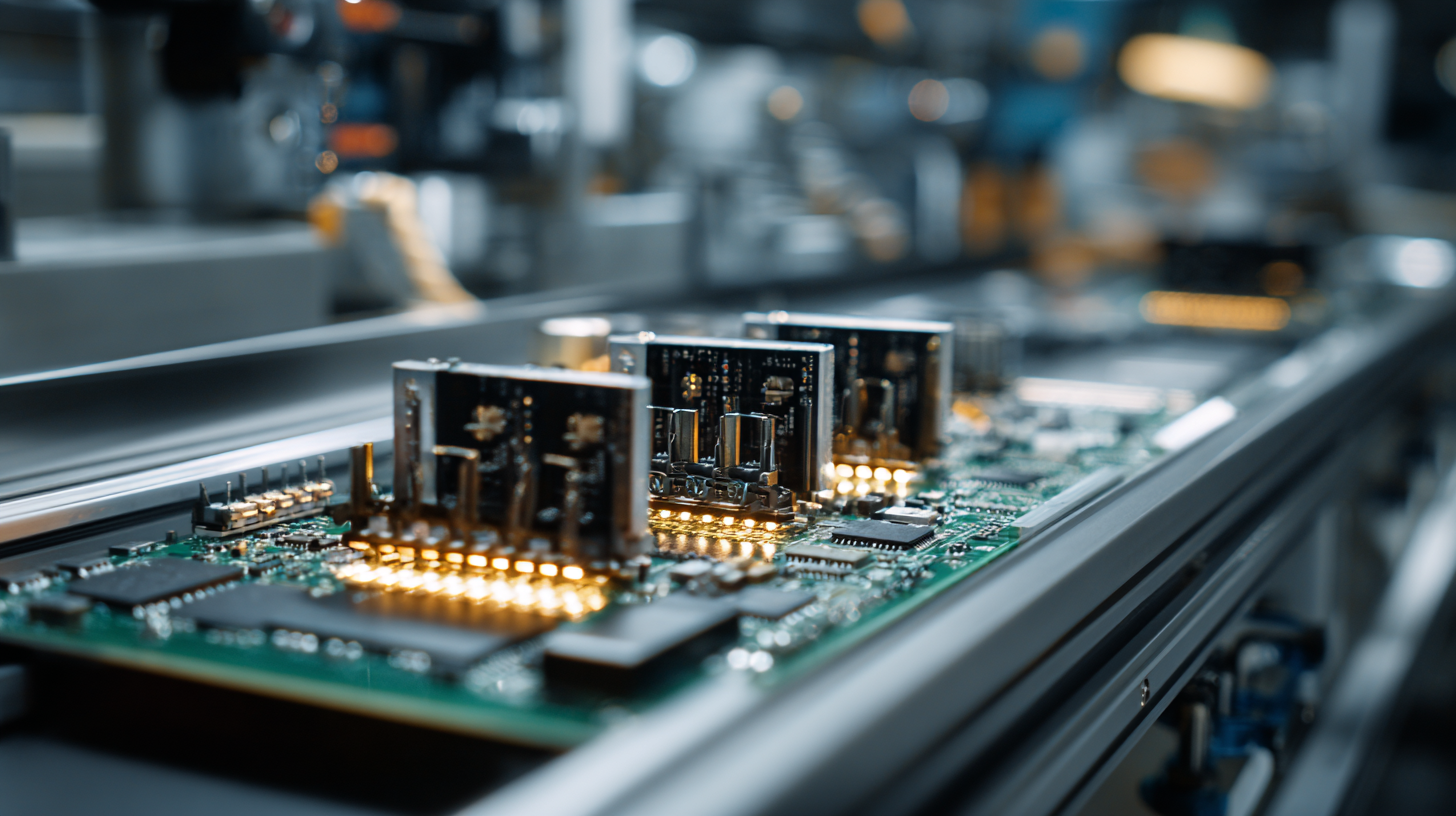

WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

Learn MoreIn the rapidly evolving landscape of global supply chains, the practice of board assembly is undergoing significant transformations driven by innovative technologies and methodologies. According to a recent report by the International Data Corporation (IDC), by 2025, over 50% of supply chain organizations will have adopted advanced technologies such as the Internet of Things (IoT) and artificial intelligence (AI) to streamline their manufacturing processes. The integration of these technologies into board assembly not only enhances efficiency but also enables real-time monitoring and data analysis, ultimately leading to quicker response times and reduced costs. Furthermore, a study published by McKinsey indicates that companies leveraging automation in board assembly can achieve up to a 70% reduction in assembly time, significantly improving their competitive edge in the market. As these innovations continue to shape the future of board assembly, businesses must adapt to these changes to optimize their operations and meet the growing demands of consumers.

The advancement of materials in board assembly plays a crucial role in the evolution of the global supply chain. Innovations such as self-assembled 3D microelectronic devices are emerging to overcome the limitations of traditional microelectronics, enabling the integration of numerous 3D components in a compact architecture. This transformative approach not only enhances device performance but also optimizes space, paving the way for more complex and efficient electronic systems.

Furthermore, the rise of biodegradable substrates for rigid and flexible circuit boards signifies a pivotal shift towards sustainable electronics. These materials align with the global push for greener solutions, reducing environmental impact while maintaining high performance. Concurrently, the development of flexible hybrid electronics is revolutionizing circuit manufacturing. By merging the benefits of printed and conventional electronics, these innovations offer greater versatility and adaptability to meet diverse application needs. Collectively, these advanced materials propel board assembly into a new era, fostering sustainability and efficiency in the ever-evolving electronics landscape.

Automation technologies are rapidly transforming the landscape of supply chain management, leading to remarkable enhancements in

efficiency and productivity. By integrating

smart robotics and artificial intelligence, companies can streamline their operations, reduce human error, and optimize

inventory management. These innovations can drastically cut down lead times, ensuring that products move seamlessly from

manufacturers to consumers.

Tip: Embrace automation tools that fit your organization's specific needs. Investing in tailored software solutions can significantly enhance visibility across the supply chain, allowing for quicker decision-making and improved responsiveness to market changes.

Furthermore, automation not only elevates operational efficiency but also provides valuable data insights. Advanced analytics can

forecast demand with higher accuracy, enabling businesses to adjust their strategies proactively. This proactive approach

facilitates better resource allocation and minimizes waste, ultimately resulting in significant cost savings.

Tip: Regularly analyze your automation processes. Continuous improvement through feedback loops can help identify bottlenecks

and further refine operations, ensuring your supply chain remains agile and competitive in a rapidly evolving market.

In today's rapidly evolving global supply chain, data analytics is revolutionizing the way board assembly processes are approached, resulting in significant cost reductions. By harnessing the power of real-time data, companies can identify inefficiencies in their production lines and make data-driven decisions that streamline operations. The ability to analyze data from various stages of assembly allows organizations to pinpoint bottlenecks, optimize workforce allocation, and refine inventory management strategies.

Moreover, predictive analytics plays a pivotal role in forecasting demand and enhancing supply chain agility. By analyzing historical data trends and market conditions, manufacturers can better anticipate fluctuations in demand, thus minimizing excess inventory and reducing holding costs. This proactive approach not only saves money but also ensures a more responsive supply chain capable of adapting to market changes swiftly. As data-driven insights become integral to decision-making in board assembly, companies are poised to achieve lower costs and improved operational efficiency.

Incorporating sustainable practices into board assembly innovations is crucial for reshaping the global supply chain towards a greener future. Recent studies emphasize how integrating circular economy principles can enhance sustainability in manufacturing processes, aligning with the global shift towards eco-friendly operations. For instance, a report by the Ellen MacArthur Foundation highlights that adopting circular strategies can reduce material consumption by up to 80%, significantly mitigating waste and fostering resource efficiency.

Moreover, the call for transformative actions from international health organizations underscores the importance of sustainability across various sectors, including pharmaceuticals. This movement is pushing for innovative practices that prioritize eco-conscious manufacturing and distribution, as evidenced by initiatives emphasizing environmental social governance (ESG). Research indicates that companies adopting strong ESG practices not only improve their sustainability performance but can also achieve higher profitability in the long term.

Small and medium enterprises (SMEs) play a vital role in this transformation by leveraging digitalization and sustainable entrepreneurship. A recent model identified in industry reports suggests that these businesses can enhance their competitiveness and resilience by embracing long-term sustainability strategies, ultimately contributing to a more sustainable board assembly framework in the supply chain.

| Innovation | Sustainable Practice | Impact on Supply Chain | Adoption Rate (%) |

|---|---|---|---|

| Automated Assembly Lines | Reduced energy consumption | Increases efficiency and reduces waste | 60% |

| 3D Printing | Use of recyclable materials | Reduces material waste and shortens production time | 45% |

| IoT Integration | Promoting real-time monitoring | Enhances supply chain transparency | 70% |

| Smart Logistics | Emission tracking | Optimizes transportation routes | 55% |

| Circular Economy Practices | Resource recovery | Minimizes waste throughout product life cycle | 50% |

The future of board assembly is increasingly intertwined with smart manufacturing solutions that enhance quality control throughout the global supply chain. By integrating advanced technologies, manufacturers can automate their processes, drastically improving decision-making and operational efficiency. This shift towards intelligent factories not only leads to higher production rates but also reduces costs and mitigates risks associated with traditional manufacturing methods.

Tips to consider include investing in predictive maintenance systems, which leverage data analytics to foresee equipment failures, ensuring uninterrupted production. Additionally, embracing protocols like IO-Link can facilitate better communication between sensors and devices, promoting transparency and smarter automation. Such innovations enable manufacturers to uphold superior quality control standards while adapting to the rapid changes demanded by the global market.

Moreover, as the smart manufacturing market anticipates substantial growth, companies must prioritize digital transformations. Collaborating with technology partners to establish digital training bases can foster a culture of innovation, equipping employees with necessary skills to thrive in this evolving landscape. Emphasizing these strategic actions will position manufacturers to leverage the full potential of Industry 4.0, enabling a more resilient and adaptable supply chain.