WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

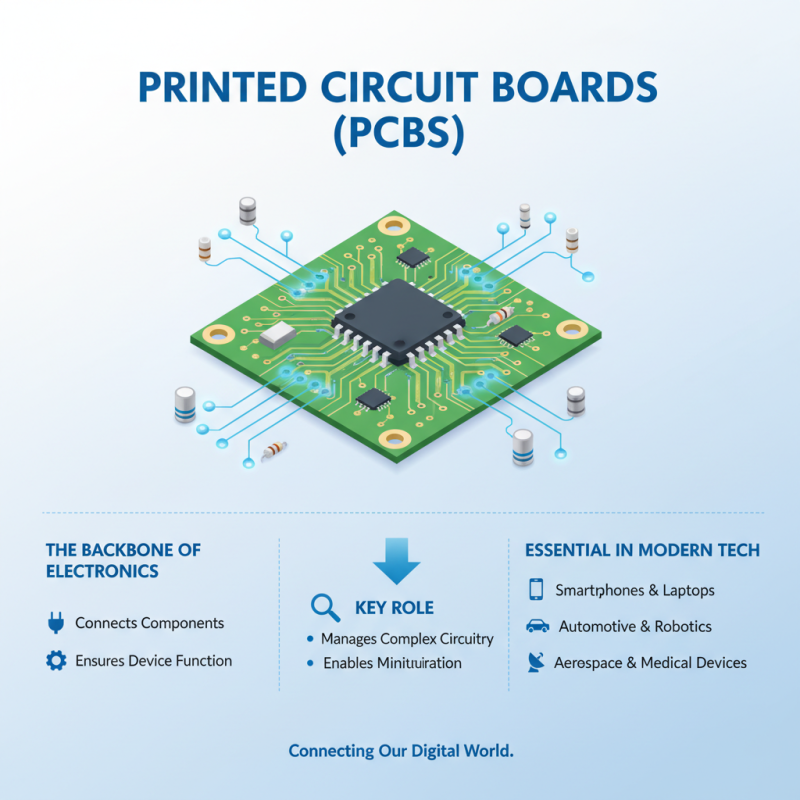

Learn MoreIn the landscape of modern electronics, the significance of the PCB circuit board cannot be overstated. As the backbone of virtually all electronic devices, PCB circuit boards facilitate the intricate interactions among various electronic components, from microprocessors to capacitors. These boards are meticulously designed to provide not only power distribution but also signal transmission, ensuring that devices operate efficiently and reliably.

Moreover, the versatility of PCB circuit boards contributes to their widespread application across multiple industries. From consumer electronics, such as smartphones and tablets, to automotive technology and medical equipment, PCBs are indispensable in delivering performance, functionality, and durability. Their ability to be tailored and scaled for different purposes highlights their fundamental role in advancing technology and innovation. Thus, understanding the importance of PCB circuit boards is essential in appreciating how modern electronics shape our daily lives and drive future developments.

Printed Circuit Boards (PCBs) play an indispensable role in modern electronics, serving as the backbone that connects various electronic components. These boards are responsible for electrically connecting and supporting components like resistors, capacitors, and microchips, ensuring that electronic devices function properly. Their ability to manage complex circuitry while maintaining compact sizes is crucial in today’s technology-driven world, where miniaturization and efficiency are paramount.

Tips: When designing a PCB, always consider the thermal management of your components. Adequate spacing and proper heat dissipation techniques can significantly enhance the reliability of your electronic device.

Moreover, PCBs are versatile and can be customized to fit a wide range of applications, from consumer electronics to industrial machinery. The integration of advanced materials and technologies, such as flexible PCBs and multilayer designs, allows for greater functionality and adaptability. This ensures that innovative technologies can be seamlessly integrated into new devices, propelling the electronics industry forward.

Tips: Always prototype your PCB design before mass production. Testing the layout and functionality will help identify potential issues and save time and resources in the long run.

Printed Circuit Boards (PCBs) serve as the backbone of modern electronics, with various types tailored to meet specific requirements across industries. Rigid PCBs are perhaps the most common type, characterized by their solid construction and reliability for electronic devices. They are commonly used in smartphones, computers, and consumer electronics. According to a report by Fortune Business Insights, the global PCB market was valued at approximately $80 billion in 2020 and is expected to grow significantly, driven mainly by demand for rigid boards in high-density applications.

Flex PCBs offer a remarkable advantage in terms of space-saving and adaptability, allowing for intricate designs that conform to complex shapes. This flexibility makes them indispensable in the automotive sector, particularly in creating lightweight systems for electric vehicles, which have seen a surge in popularity. A market analysis by Research and Markets indicates that the flexible PCB segment is projected to grow at a CAGR of over 10% through 2027, highlighting their increasingly vital role in innovative electronic solutions.

Lastly, the emerging trend of hybrid PCBs combines features from both rigid and flexible boards, making them suitable for advanced applications like wearable technology and IoT devices. These boards support harsh environments while providing the advantages of flexibility and conductivity, which are crucial for future applications as seen in the growing sector of smart wearable devices. This diverse array of PCB types underscores their essential role in driving electronics innovation and expanding capabilities across numerous applications in the industry.

Printed Circuit Boards (PCBs) play a crucial role in modern consumer electronics, serving as the backbone for countless devices we use daily. From smartphones to home appliances, PCBs provide the necessary electrical connections between various components, ensuring efficient operation and reliable performance. Their versatility allows them to be designed in various sizes and configurations, meeting the specific needs of different devices. For instance, multi-layered PCBs facilitate compact designs in smartphones, while flexible PCBs are increasingly popular in wearable technology.

Tips: When selecting a PCB for your project, consider the specific requirements such as size, material, and the number of layers. Additionally, assess the thermal and electrical performance needed for your application to ensure optimal functionality.

The applications of PCB technology extend beyond traditional electronics. In the realm of consumer gadgets, devices like tablets, gaming consoles, and smart home systems all rely heavily on PCBs for their internal circuitry. The increasing demand for multifunctional devices has propelled innovations in PCB design, leading to improvements in speed and energy efficiency. As electronics continue to evolve, the significance of PCBs in consumer technology remains undeniable, driving advancements that enhance our everyday experiences.

Tips: Always keep abreast of the latest PCB technologies and trends, as innovations can significantly impact the performance and capabilities of your electronic designs. Exploring new materials and manufacturing techniques can open up exciting possibilities for your products.

The design of printed circuit boards (PCBs) is fundamentally important in determining the performance and reliability of modern electronics. A study by IPC, a global association for the electronics industry, highlights that nearly 80% of electronic failures can be traced back to design issues during the PCB development phase. This underlines the critical role that optimized PCB design plays in enhancing product longevity and functionality. Well-executed designs incorporate factors such as trace routing, impedance control, and thermal management, which are vital for minimizing signal loss and enhancing overall circuit performance.

Furthermore, advancements in PCB technology, such as the adoption of multi-layer boards and flexible PCBs, have significantly contributed to performance improvements. According to a report by MarketsandMarkets, the global PCB market is projected to reach $85.26 billion by 2024, driven by the increasing complexity of electronic devices and a growing demand for high-frequency applications. As devices become smaller and more complex, the implications of PCB design on reliability become even more pronounced, with compact designs requiring innovative solutions to mitigate issues like heat dissipation and vibrations. Ensuring precision in the design phase not only enhances performance but also fosters greater reliability in the field, ultimately impacting the end user experience positively.

| Application | PCB Types | PCB Layers | Key Benefits | Impact on Performance |

|---|---|---|---|---|

| Consumer Electronics | Single-Sided, Multi-Layer | 2-6 Layers | Compact Design, Cost-Effective | Enhanced Signal Integrity |

| Automotive | Rigid, Flexible | 4-12 Layers | High Durability, Thermal Management | Reliability Under Vibration |

| Telecommunications | High-Frequency PCBs | 2-8 Layers | High-Speed Performance | Reduced Latency |

| Medical Devices | Multi-Layer, Rigid-Flex | 4-10 Layers | Miniaturization, Safety | High Reliability in Critical Applications |

| Aerospace | Lightweight, High-Performance | 6-12 Layers | High Reliability, Shock Resistance | Optimized for Harsh Environments |

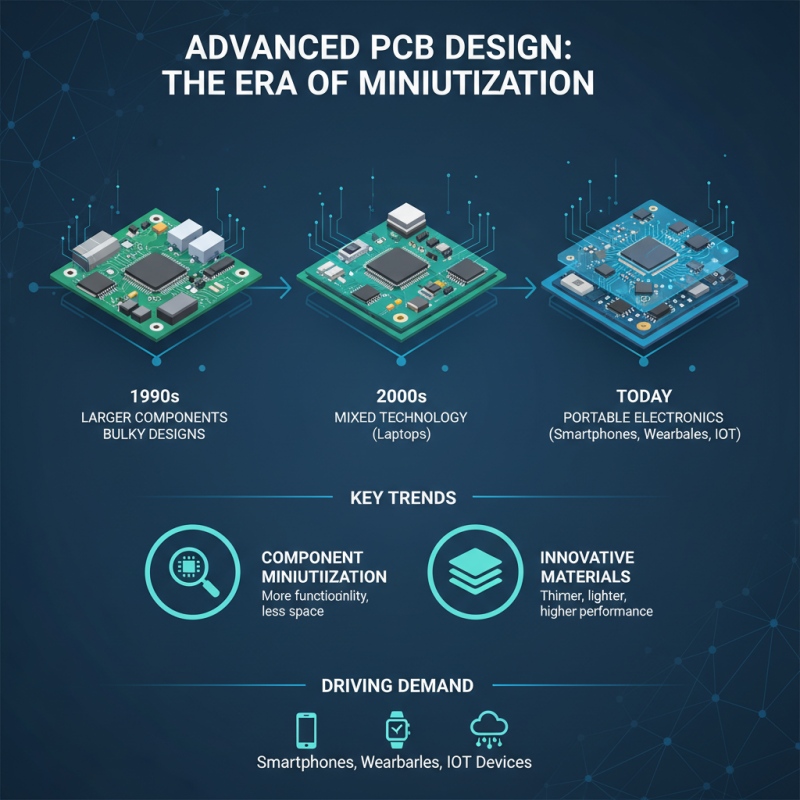

As technology continues to evolve, the development of PCB circuit boards is becoming increasingly advanced. One significant trend is the miniaturization of components, allowing for more compact designs without sacrificing functionality. This shift is driven by the growing demand for portable electronics such as smartphones, wearables, and IoT devices, where space is at a premium. Manufacturers are exploring innovative materials and design techniques to create thinner, lighter-PCBs that can maintain performance while accommodating complex circuitry.

Another notable trend in PCB innovation is the integration of smart technology. With the rise of automation and smart devices, PCBs are now being equipped with various sensors and embedded systems, enabling real-time data processing and connectivity. This trend facilitates the proliferation of smart homes, automotive systems, and industrial applications where efficiency and intelligence are paramount. Additionally, advancements in manufacturing processes, such as additive manufacturing, are paving the way for more flexible design options and faster production times, ensuring that PCBs can meet the dynamic needs of modern electronics.