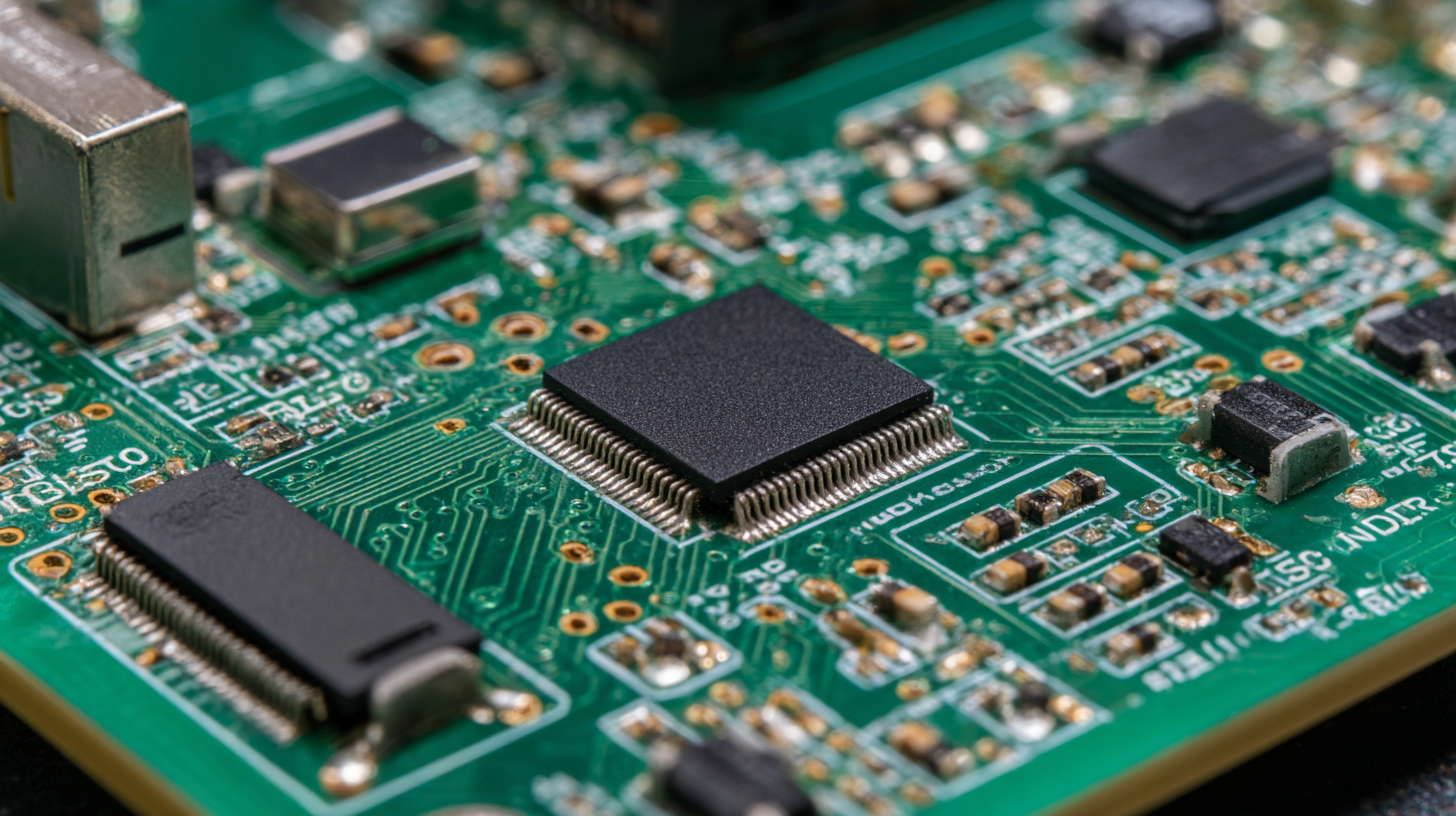

WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

Learn MoreIn the rapidly evolving landscape of electronics, the demand for high-quality printed PCB boards has never been greater. According to a recent report by Mordor Intelligence, the global printed circuit board market is projected to reach a staggering USD 85.14 billion by 2026, growing at a CAGR of 3.4% from 2021. This growth is driven largely by the rising adoption of advanced technologies like IoT, AI, and smart devices that rely heavily on sophisticated PCB designs.

Consequently, buyers worldwide are seeking top-tier manufacturing solutions that can deliver exceptional performance and reliability. Among global manufacturers, China stands out with its state-of-the-art factories offering cutting-edge technology and stringent quality control processes.

This blog will delve into the technical specifications of the best printed PCB boards available in the market today, offering insights that empower buyers to make informed decisions.

The demand for high-quality printed PCB boards is being driven by several key factors that reflect the evolving landscape of global markets. As industries increasingly rely on advanced electronic components, the need for reliable and efficient printed circuit boards has surged. The rapid expansion of the semiconductor and electronic parts market, which is projected to reach an astounding value of over $1.39 trillion by 2024, emphasizes the growing importance of PCBs in various applications, including smartphones, laptops, and smart home devices.

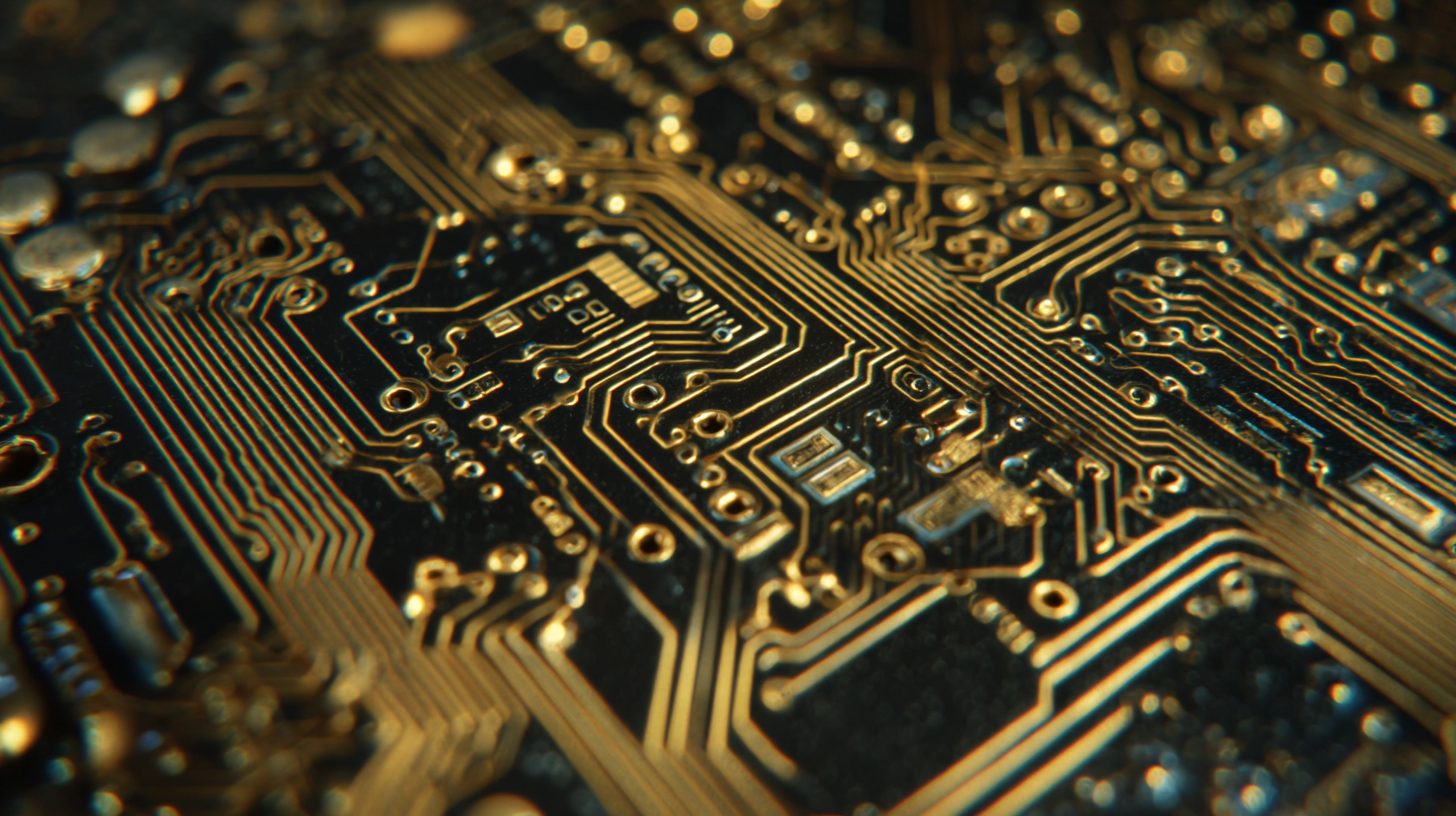

Additionally, the global shift towards renewable energy solutions, particularly solar technology, has further heightened the demand for flexible substrates used in PCBs. These flexible materials play a crucial role in enhancing the efficiency and performance of solar panels, enabling manufacturers to develop innovative and sustainable energy solutions. As more companies strive to embrace environmentally friendly practices, the push for high-quality printed PCBs will only intensify, shaping the future of electronics and energy sectors alike.

The choice of PCB material plays a crucial role in determining the performance and durability of printed circuit boards. According to a recent report from IPC (Institute for Printed Circuits), nearly 50% of PCB failures are attributed to material-related issues, emphasizing the need for careful selection.

Fr4, a widely used material, offers a good balance of price and performance, making it a staple in the industry. However, it may not withstand extreme temperatures and conditions, which is critical for applications in automotive or aerospace sectors.

Fr4, a widely used material, offers a good balance of price and performance, making it a staple in the industry. However, it may not withstand extreme temperatures and conditions, which is critical for applications in automotive or aerospace sectors.

Advanced materials such as Polyimide and Rogers are increasingly gaining traction due to their superior heat resistance and dielectric properties. Research indicates that PCBs utilizing Polyimide can operate effectively in temperature ranges from -269°C to +400°C, significantly outperforming traditional materials in high-temperature applications. Additionally, Rogers substrates are favored in high-frequency applications, as they can reduce signal loss and improve overall circuit performance. As the demand for high-performance electronics continues to rise, understanding the implications of PCB material types becomes essential for global buyers looking to ensure reliability in their products.

In the realm of printed circuit boards (PCBs), selecting the right surface finish is crucial for ensuring both functionality and reliability. Among the various surface finish options available, techniques such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative) are pivotal for meeting the specific needs of global buyers. According to recent industry reports, approximately 35% of PCB defects are linked to inadequate surface finishes, highlighting the need for consistency and quality in production processes.

Furthermore, the shift towards sustainable practices is also influencing PCB manufacturing. As machine learning continues to advance, there is a growing application of data-driven modeling in optimizing PCB designs for enhanced durability while minimizing waste. The integration of AI technologies aims to streamline the production process, reduce material usage, and align PCB manufacturing with principles of resource circularity. Research indicates that companies leveraging such technologies can improve efficiency by up to 20%, underscoring the importance of innovative approaches in the PCB industry. By embracing these advancements, manufacturers can not only enhance the performance of their products but also contribute to a more sustainable future.

| PCB Type | Layer Count | Surface Finish | Material Type | Max Frequency (GHz) | Thermal Conductivity (W/mK) |

|---|---|---|---|---|---|

| FR-4 | 2 | HASL | Epoxy Glass | 2.0 | 0.3 |

| HDI | 4 | ENIG | High Tg FR-4 | 3.5 | 0.4 |

| Alumina | 1 | OSP | Ceramic | 10.0 | 20 |

| Rigid-Flex | 6 | Immersion Gold | Polyimide | 5.0 | 0.2 |

| Teflon | 2 | ENEPIG | Teflon | 4.0 | 0.1 |

The manufacturing process of printed circuit boards (PCBs) significantly influences their quality and cost efficiency, making it a crucial consideration for global buyers. From material selection to production techniques, every step impacts the final product's performance and reliability. For instance, high-grade materials may elevate the initial costs, but they often result in superior thermal management and electrical performance, ultimately enhancing the longevity of the electronic devices.

Moreover, the choice of manufacturing processes, such as surface mount technology versus through-hole technology, plays a vital role in determining both the quality and efficiency of production. Advanced techniques like automated assembly and precision soldering can reduce human error and minimize defects, thereby increasing the yield rate. In contrast, traditional methods may still hold merit in specific applications but can lead to inconsistencies that compromise product reliability. Therefore, understanding these manufacturing intricacies is essential for buyers aiming to strike a balance between quality and cost in the highly competitive electronic market.

In the realm of printed circuit boards (PCBs), compliance with international standards and certifications is crucial for ensuring product quality and reliability. As global buyers seek to source PCBs from various regions, they must evaluate manufacturers' adherence to established industry guidelines such as IPC, RoHS, and ISO certifications. These certifications not only signify that the products meet specific technical requirements but also demonstrate a commitment to sustainable practices, which is increasingly important in today's environmentally conscious market.

The recent developments in the Dominican Republic highlight its potential to contribute to global semiconductor and PCB supply chains. As this vibrant economy positions itself to attract investments, buyers can expect enhanced manufacturing capabilities compliant with international standards. As the Dominican Republic strengthens its infrastructure and workforce, it opens doors for globally sourced PCBs that meet rigorous compliance criteria. This alignment with best practices will ensure that the PCBs produced are not only of high quality but also capable of meeting the diverse needs of buyers worldwide.

This chart represents the compliance standards and certifications of various globally sourced printed PCB boards. The bars indicate the number of PCBs compliant with different international standards.