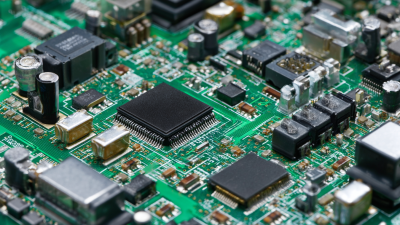

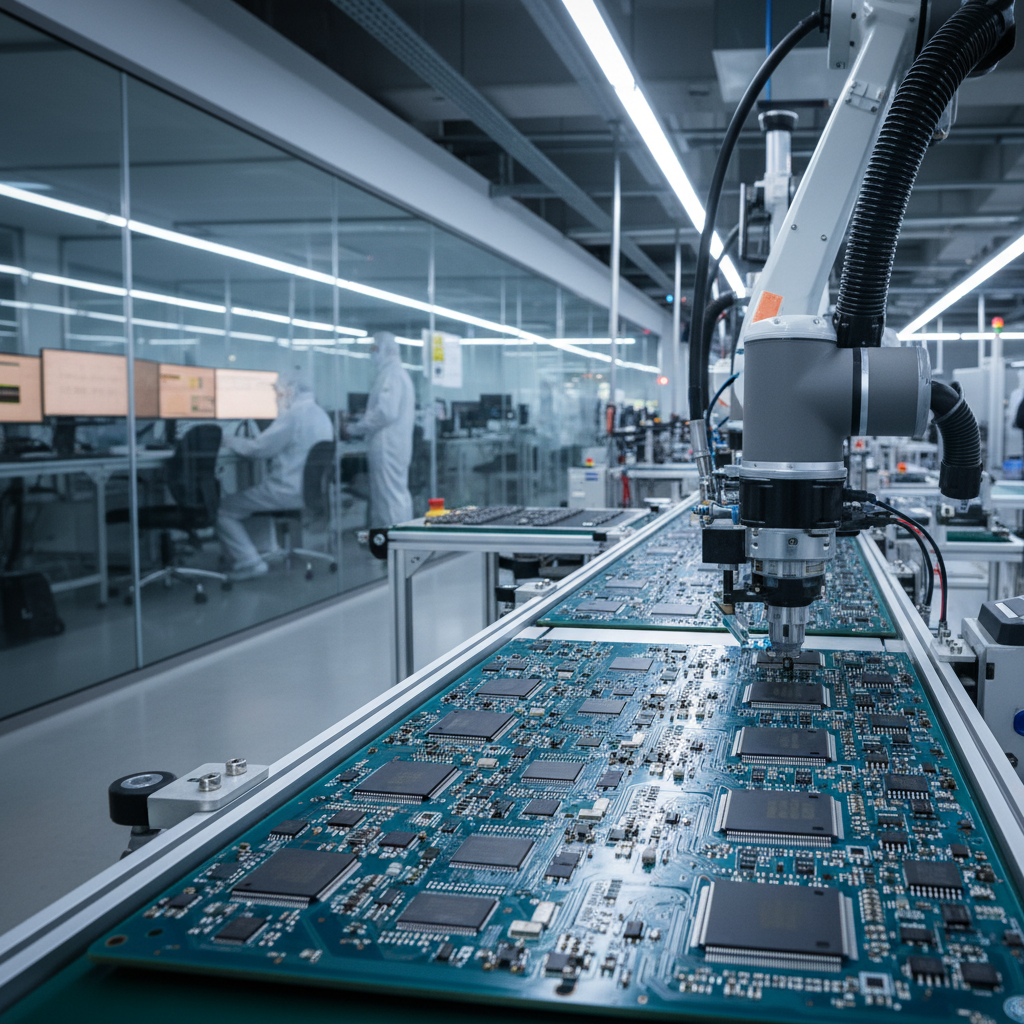

WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

Learn MoreIn the rapidly evolving landscape of technology, the demand for high-quality electronics PCB assembly services has surged, driven by the need for efficient production and reliable performance in various applications. According to a recent report by Market Research Future, the global PCB assembly market is expected to reach $75 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.1% from 2020 to 2025. This growth underscores the critical role that these services play in industries ranging from consumer electronics to automotive and telecommunications.

Industry expert Dr. Emily Chen, a leading figure in electronics manufacturing, emphasizes the importance of selecting the right PCB assembly partner, stating, "The efficiency and quality of electronics PCB assembly directly impact the reliability of the final product." Her insights are echoed by numerous case studies highlighting the significant cost savings and performance improvements achieved when companies invest in high-quality assembly services. As businesses navigate the complexities of modern electronic design and manufacturing, understanding the top players in the electronics PCB assembly market becomes essential for ensuring optimal product development and market success.

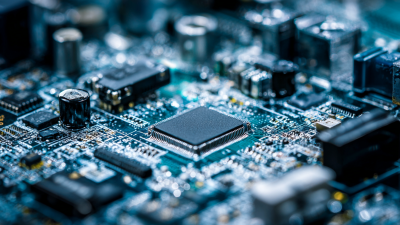

The printed circuit board (PCB) assembly market is experiencing significant transformations in 2023, influenced by various trends shaping the electronics industry. With a projected market size reaching USD 161.6 billion and an anticipated compound annual growth rate (CAGR) of 5.0%, the demand for quality PCB assembly services is expected to surge. Automation is emerging as a key driver, with electronic manufacturing services (EMS) increasingly adopting innovative technologies to enhance production efficiency and reduce operational costs. This focus on automation not only streamlines processes but also improves the consistency and reliability of electronic components.

In parallel, India's electronics manufacturing sector presents both challenges and opportunities, propelled by government initiatives and a growing domestic market. By capitalizing on the rising demand for active components, such as diodes and integrated circuits, the country is positioning itself as a vital player in the global supply chain. The global semiconductor and electronic parts market is projected to witness robust growth, driven by advancements in technology and increasing reliance on electronic devices across various sectors. These developments underscore the vital role that PCB assembly services will play in meeting the evolving needs of the electronics industry in the coming years.

When selecting an electronics PCB assembly service, evaluating key metrics for quality is essential to ensure efficiency and reliability. One of the primary metrics to consider is the defect rate, which indicates the number of errors found in the production process. A low defect rate is crucial for maintaining high standards and can significantly save costs in the long run. Additionally, lead time is another vital factor; a shorter lead time not only accelerates product development but also reflects a service's operational efficiency.

**Tips:** When assessing a potential PCB assembly service, request detailed reports on their defect rates and average lead times. This information will provide valuable insights into their quality control processes and overall performance. Consider also the technology they use — advanced equipment and skilled personnel often result in better assembly quality.

Moreover, customer feedback is an important metric to evaluate. Reviews and ratings can offer a glimpse into other businesses' experiences, indicating reliability, communication, and post-production support. A service that prioritizes customer satisfaction and maintains an open line of communication is likely to provide higher quality and efficiency during the assembly process.

**Tips:** Don’t hesitate to ask for references or case studies from the PCB assembly service. This can help you gauge their ability to meet specific requirements and adapt to varying project demands, further ensuring a successful partnership.

This chart illustrates the quality and efficiency scores for the top 10 PCB assembly services. The comparison helps in evaluating the performance of different services in the electronics manufacturing industry based on key metrics.

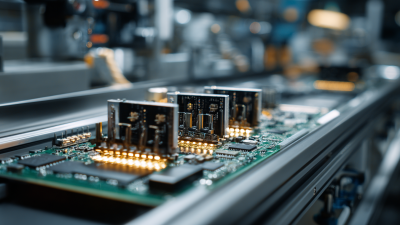

The impact of automation on PCB assembly efficiency is profound, revolutionizing the way electronic manufacturing services operate. With the global IoT in manufacturing market poised for significant growth, reaching an estimated $141.18 billion in 2025, it's clear that the integration of automated solutions is driving this transformation. Automated technologies reduce manual errors, streamline production processes, and enhance the overall quality of PCB assembly. The data indicates that companies adopting these advanced systems are witnessing substantial improvements in efficiency, leading to faster turnaround times and reduced costs.

As highlighted in recent industry events, the focus on smart factory technologies and data-driven manufacturing is reshaping the landscape of PCB assembly. Automated inspection systems utilizing computer vision are emerging as standard practice, allowing for real-time quality control and faster defect detection. Furthermore, the convergence of automation and artificial intelligence in data analytics provides manufacturers with insights that were previously unattainable, helping them make informed decisions that enhance production reliability and efficiency. This synergy not only accelerates assembly processes but also ensures higher standards in product performance, solidifying automation's role as a cornerstone of modern electronics manufacturing.

In the competitive landscape of electronics manufacturing, balancing quality and cost is crucial for businesses looking to succeed. The printed circuit board (PCB) assembly market, projected to reach USD 161.6 billion by 2035 with a steady growth rate of 5.0% CAGR, emphasizes the importance of finding reliable assembly services that cater to both high standards and budget constraints. Companies are increasingly turning to specialized PCB assembly services that promise efficiency without compromising on the quality of components.

Amid rising costs, businesses can secure favorable pricing by locking in costs before they escalate. Firms have started implementing strategies to ensure component authenticity and price management effectively. By streamlining the manufacturing process and focusing on mass production techniques, manufacturers can offer cost-effective bulk solutions that meet the demands of their clients. This trend not only enhances productivity but also allows businesses to stay competitive in a rapidly evolving market. As organizations navigate these dynamics, the importance of choosing a trustworthy assembly partner cannot be understated, as it ultimately impacts overall performance and customer satisfaction.

When selecting a printed circuit board (PCB) assembly service, it's crucial to consider several key factors that impact quality and efficiency. Firstly, it's essential to evaluate the company's capabilities in both surface mount technology (SMT) and through-hole assembly. According to a 2022 report by the IPC (Association Connecting Electronics Industries), approximately 70% of manufacturers prioritize service providers with expertise in advanced assembly techniques to ensure optimal performance and durability of the final product.

Additionally, transparency in communication and project management practices is vital. A 2023 survey indicated that 58% of businesses experienced delays in production due to poor reporting and lack of updates from assembly partners. Therefore, a service that offers real-time tracking and frequent updates can significantly enhance overall efficiency. It's also advisable to examine the manufacturer’s certifications, such as ISO 9001 and IPC-A-610, as these can serve as indicators of a provider's commitment to quality standards.

Finally, consider the lead times and scalability of the production process. A report from Electronics Weekly highlighted that companies with flexible production capabilities are 40% more likely to meet urgent project deadlines. A service that can adapt to varying order sizes while maintaining speed and accuracy is invaluable in the fast-paced electronics industry.

| Service Type | Lead Time (Days) | Production Capacity (Boards/Month) | Quality Certification | Specialization |

|---|---|---|---|---|

| Prototype Assembly | 5-7 | 500 | ISO 9001 | Prototypes & Low Volume |

| Mass Production | 15-20 | 50,000 | ISO 13485 | High Volume Electronics |

| Quick Turn Assembly | 3-5 | 1,000 | IPC-A-610 | Fast Turnaround |

| Mixed Technology | 10-15 | 5,000 | UL Certification | Through-Hole & SMT |

| High-Reliability Assembly | 20-30 | 1,000 | AS9100 | Aerospace & Defense |

| Automated Assembly | 15-25 | 20,000 | ISO 9001 | Fully Automated Lines |

| Small Batch Assembly | 7-10 | 200 | ISO 9001 | Customization |

| Hybrid Assembly | 10-15 | 3,000 | IPC-A-610 | Hybrid Technology |

| Enclosure Assembly | 20-30 | 1,500 | ISO 14001 | Final Assembly & Testing |

| On-Demand Assembly | Flexible | Variable | Various | Customize per Client Needs |